The Acoustics of Dropped Weights

The Physics Behind It:

The Law of Conservation of Energy says within a closed system, energy can neither be created nor destroyed. So the total energy within a system, for example weights being dropped on a floor, always remain constant. Upon impact, all of the energy from the falling weight gets redistributed in the following 3 ways:

The Law of Conservation of Energy says within a closed system, energy can neither be created nor destroyed. So the total energy within a system, for example weights being dropped on a floor, always remain constant. Upon impact, all of the energy from the falling weight gets redistributed in the following 3 ways:

- Reflected back into the falling object: as seen when a weight rebounds back up.

- Transmitted through the flooring into adjacent areas as sound and vibrational energy.

- Absorbed by the flooring

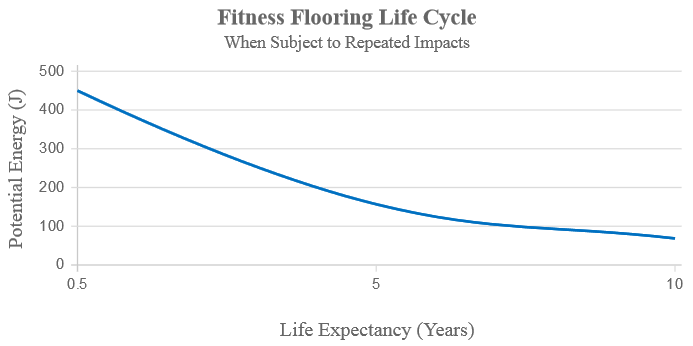

The more energy a product absorbs, the shorter its life cycle.

For a product to absorb a lot of energy, it must be made of a material that will deflect, allowing the falling object to penetrate or sink into the material. This effectively minimizes the force of impact. Unfortunately, it wouldn’t be practical to cover a gym floor with something like foam. Something this soft wouldn’t be durable enough to last very long, and it would not provide a good base for athletes to exercise on.

When it comes to lifting weights, athletes prefer and need a firm foundation to press into.Enter Ecore. Ecore products feature performance crumb rubber. Not only is rubber more durable than foam; but, since it’s an elastomeric material, it possesses an internal damping factor. This damping dissipates energy, reducing the amount of deflection needed to absorb energy from an impact. The result: a firm yet energy absorbing foundation that meets all physical requirements while maximizing acoustical performance.

When it comes to lifting weights, athletes prefer and need a firm foundation to press into.Enter Ecore. Ecore products feature performance crumb rubber. Not only is rubber more durable than foam; but, since it’s an elastomeric material, it possesses an internal damping factor. This damping dissipates energy, reducing the amount of deflection needed to absorb energy from an impact. The result: a firm yet energy absorbing foundation that meets all physical requirements while maximizing acoustical performance.

Acoustic Performance

In the US, the acoustic properties of flooring are currently limited to:

In the US, the acoustic properties of flooring are currently limited to:

- Impact Insulation Class (IIC): For structure-borne sound and vibration transmission.

- Sound Transmission Class (STC): For airborne sound transmission.

- The majority of acoustical energy generated by dropped weights falls in the range between 25-400 hertz. IIC Ratings don’t include that full range.

- The impact source in an IIC test consists of 1 pound hammers being dropped from 1.5 inches high. This wouldn’t even come close to simulating the types of weight drops that occur in a gym.

IIC ratings can be a helpful reference, but they don’t provide you with a complete picture of the acoustic problem at hand.

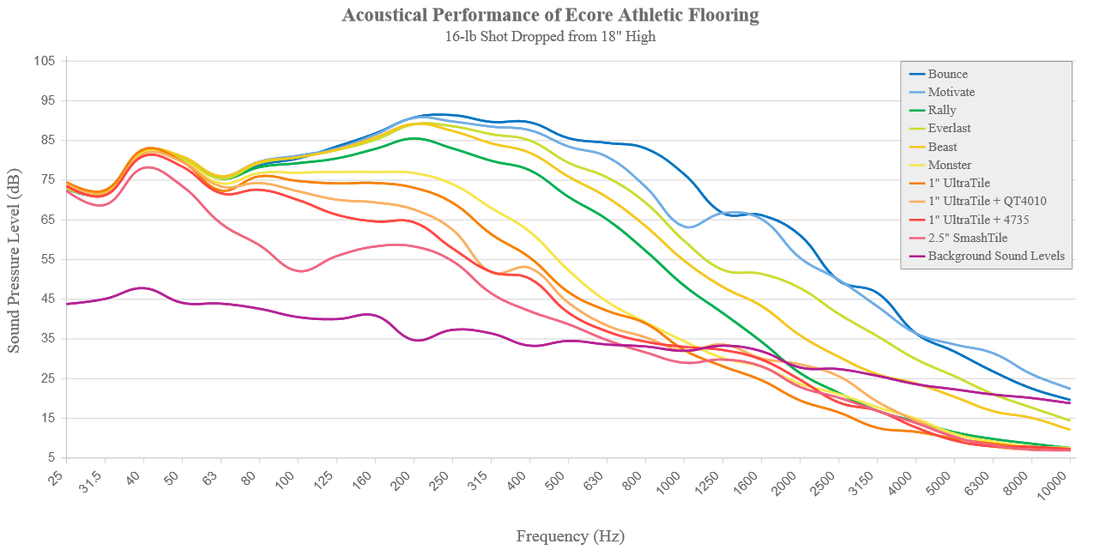

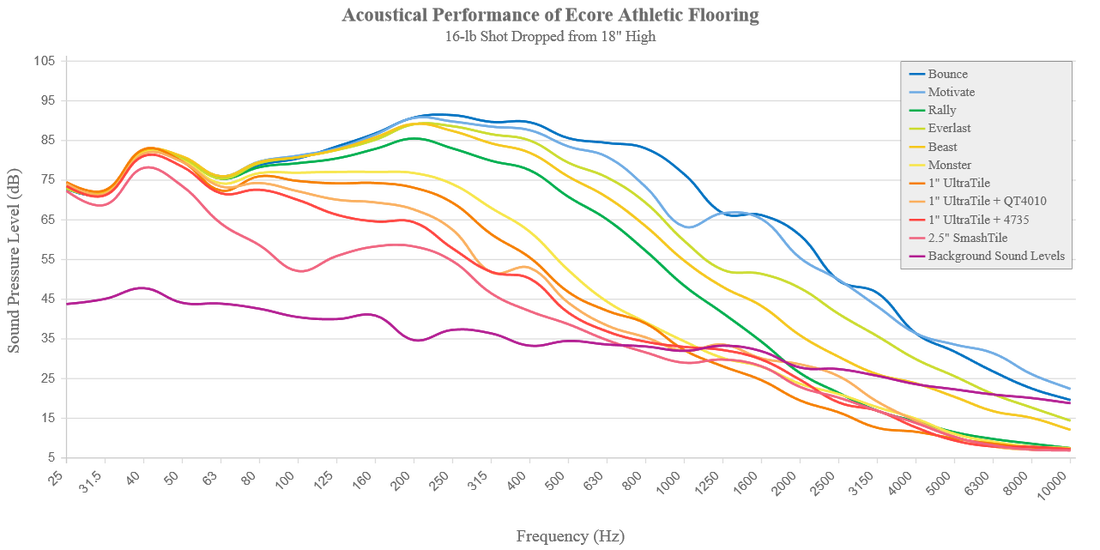

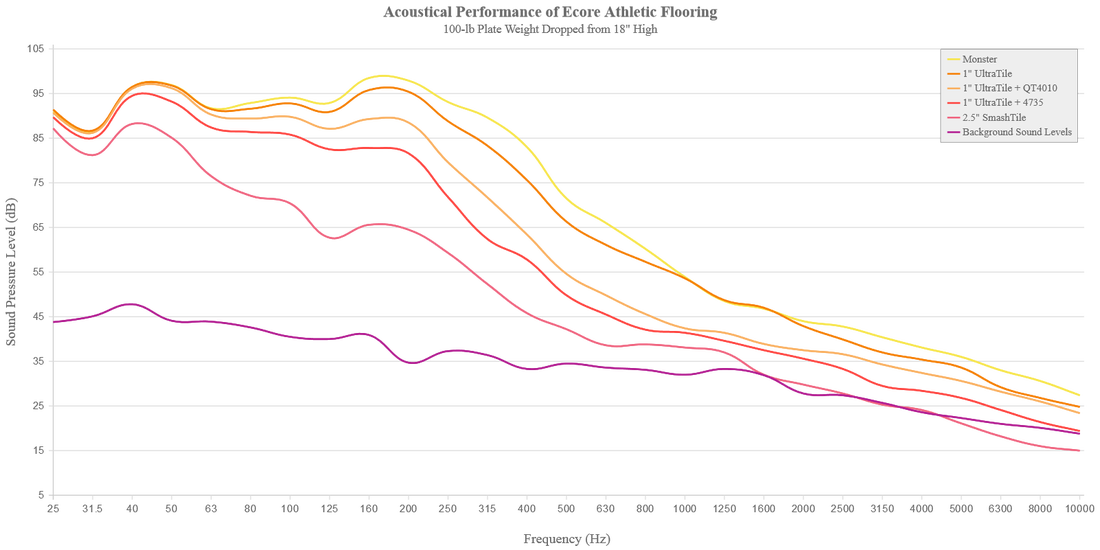

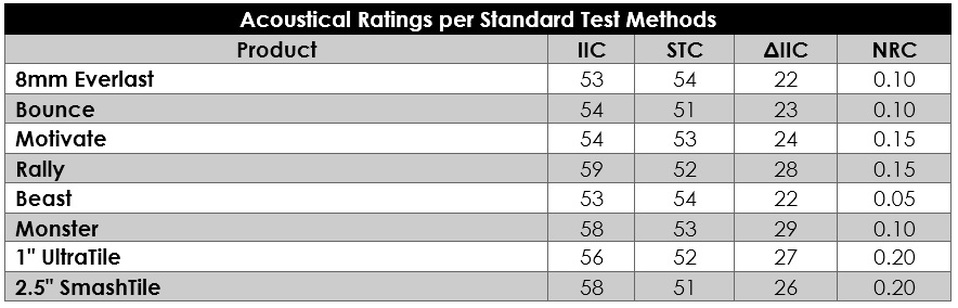

So in addition to providing you with standard IIC, STC, and NRC ratings, Ecore has conducted dozens of lab test to provide as much acoustical data as possible for a variety of scenarios. Below are the results that compare how Ecore Athletic surfaces performed with:

- A 16-lb shot being dropped from 18” high

- A 35-lb kettlebell being dropped from 18” high

- A 100-lb plate weight being dropped from 18” high

- Rhythmic stepping to simulate aerobic activity

- All tests were performed on a 6” concrete slab base structure with no ceiling below.

- Results in the field will vary based on each facility’s floor-ceiling assembly.

- If you are working with an engineer, have them contact Ecore to receive the full 1/3 octave band data to complete their analysis.

These sound transmission tests (IIC, STC, ∆IIC) were performed over a 6” concrete slab with no ceiling below. A large volume of tests were conducted in a short period to provide a baseline comparison of product performance without the presence of external variables. As such, no adhesive was used. Please note: adhesives and installation methods may yield varied results.

Ecore vs. The Competition

- Ecore Athletic products featuring performance rubber are proudly made in the USA.

- Ecore Athletic products feature wear layers that provides durability, slip-resistance, and force distribution.

- Many competitors are using ISO (International) and JIS (Japanese) methods for their acoustical testing, none of which translate well into American requirements. Their “heavy” impact testing only consists of a 5.5-lb rubber ball.